The weighing process of microingredients, which form the backbone of many food recipes, needs to guarantee precision, quality, repeatability, and traceability. This is where Lawer’s automatic weighing systems come into play, offering a multitude of advantages and benefits to food manufacturers.

Precision and Quality

Lawer’s systems ensure the exact measurement of micro-ingredients, maintaining the highest quality of the finished product. Lawer’s systems offer different levels of accuracy, ranging from 1g to 0.01g, catering to diverse production needs.

Repeatability and Consistency

By eliminating human error, these systems ensure that every batch produced is consistent in quality and taste; They are designed to maintain the right balance of raw materials, ensuring that each product meets the same high standards, and granting the perfect repeatability of the recipes.

• Efficiency and Cost Reduction

Lawer’s systems streamline the production process, reducing the time required for weighing microingredients with high precision. This optimization leads to higher productivity and lower operational costs.

• Traceability and Safety

Both SUPERSINCRO and UNICA systems are equipped with advanced control software that guarantees effective cross-checks and traceability. This software generates sophisticated reports and allows seamless integration with external systems (MES), aligning with Industry 4.0 standards.

Additionally, these systems maintain perfect hygiene and safety in handling, using stainless steel silos and efficient suction-filtering devices to ensure a clean working environment.

• Confidentiality and Know-How

SUPERSINCRO and UNICA can safeguard this confidential information, ensuring that know-how remains protected. This protection is crucial for maintaining a competitive edge in the market.

• Customization and Flexibility Lawer’s systems can be customized to meet specific production requirements: systems like SUPERSINCRO offer customizable solutions for various products and production scales, enhancing the versatility and adaptability of the manufacturing process.

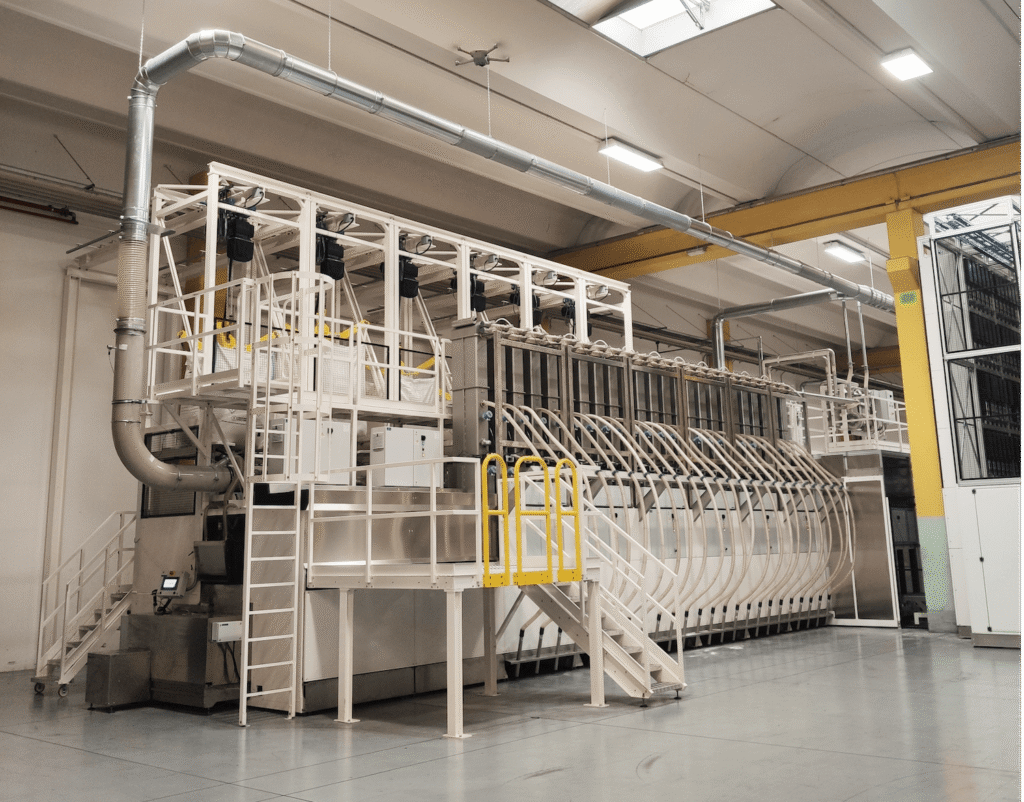

Supersincro

• Totally customizable

• Silos (fixed and interchangeable), hoppers, big bags for the storage of products (from 200 to 1800 l)

• Automatic generation of bags of variable size (from 9 to 36 l)

• One bag with a recipe every 30 seconds

• Loading of the products by gravity or vacuum

• Double dosing screw and anti-clogging devices

• Efficient suction-filtering device

• Control software integrated with external systems

• Ideal for large productions

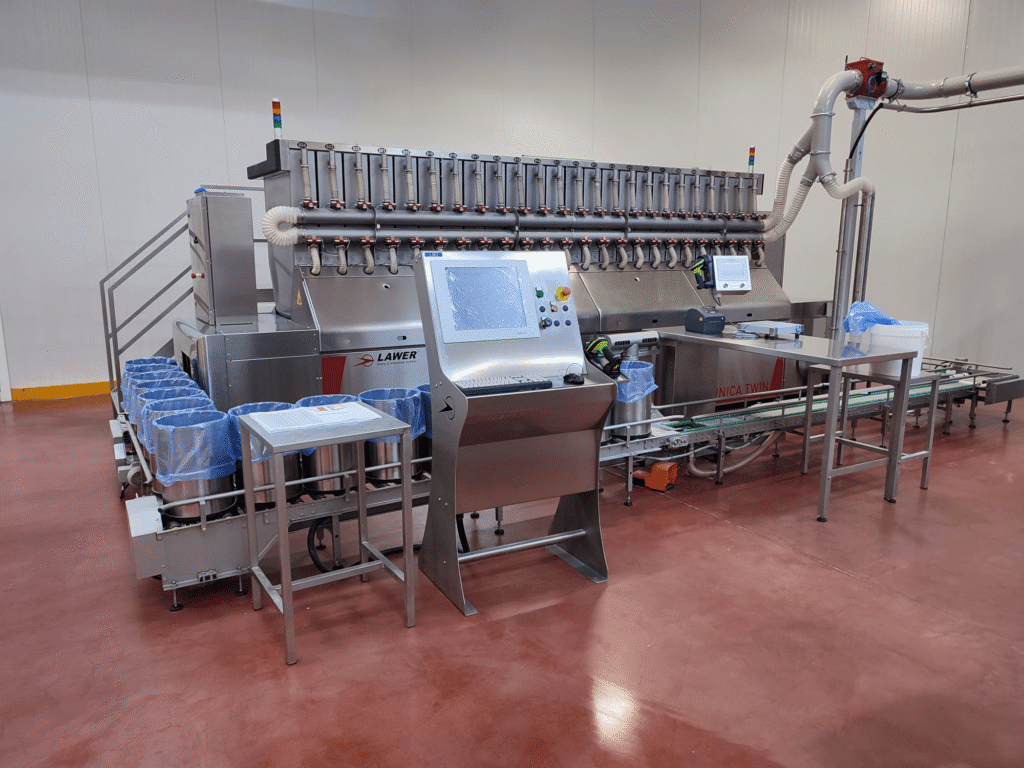

Unica Twin

• 12, 24 or 36 stainless-steel silos, capacity 100 l

• One or two scales, with a precision of 0,1 g

• Loading of the products by gravity or vacuum

• Dosing screw and anti-clogging devices

• Efficient suction-filtering device

• Control software integrated with external systems

• Ideal for small-medium productions

Unica HD

• 8-16 or 24 silos, capacity 50 l

• Stainless-steel screws

• One electronic scale, capacity 30kg and resolution 1g

• Loading of the products by gravity

• Control software integrated with external systems

• Ideal for small-medium productions

Advanced Technology and Innovation

Lawer, an Italian company founded in 1970, has developed advanced technologies and know-how in the automatic weighing of powder and liquid products.

Their expertise in single- or multiweighing systems has made them a trusted partner in the food industry. Continuous investments in safety and improvement of the working environment further enhance the reliability and efficiency of their systems.