The food processing sector is an industry where strict regulatory requirements have a powerful impact on production.

This forces manufacturers of industrial machinery to comply with stringent protocols and undergo frequent certifications. As a result, it is crucial for design teams to rely on high-quality, dependable components.

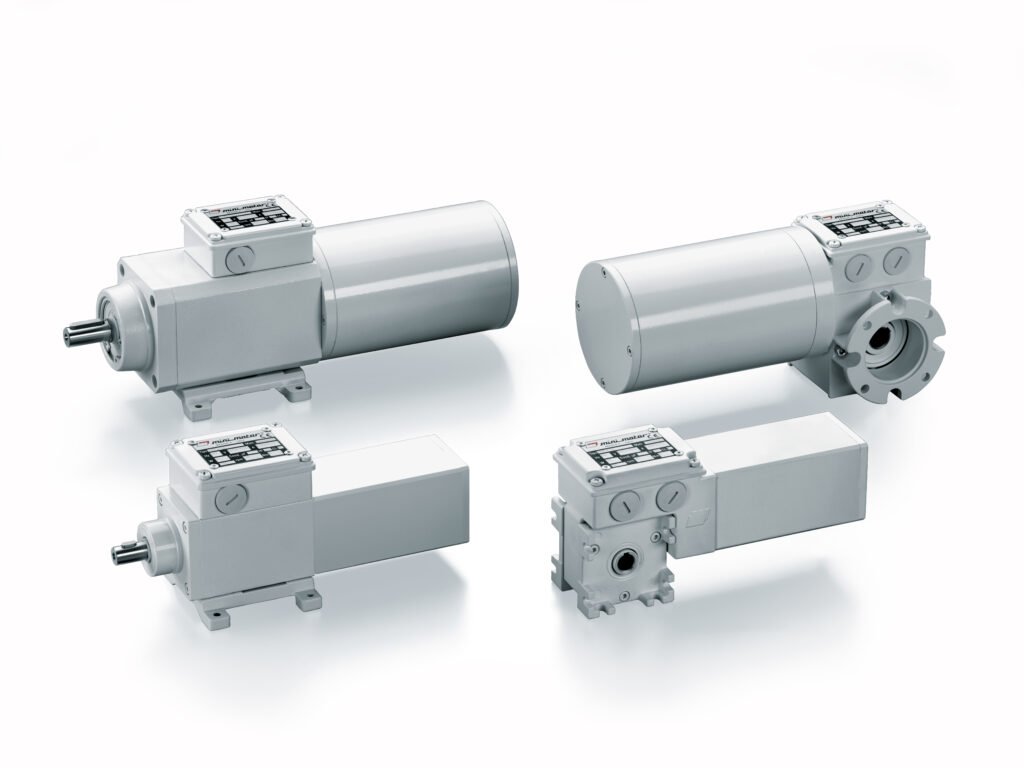

The Mini Motor Stainless Steel Line offers a state-of-the-art solution for drives operating in critical environments.

These motors are designed for direct contact with food production and can withstand frequent high-pressure washdowns. With an IP69K protection rating, our AISI 316L stainless steel servomotors can be equipped with either a 2-pole resolver or an absolute encoder when paired with a drive.

Born from the Emilia-Romagna region’s long-standing tradition in food processing, where Mini Motor‘s manufacturing plants are located, the SS Line has been refined through real-world customer applications, particularly in the dairy sector.

This includes systems where servomotors are either immersed in liquid foodstuffs or exposed to aggressive cleaning agents and high-pressure washing.

The SS gearmotors provide a wide range of reduction ratios in right-angle and inline configurations, available in both worm and planetary variants.

The smooth, polished surfaces of these servomotors fully comply with EHEDG hygiene guidelines. This same design philosophy, which eliminates edges and corners, has now been extended to the associated gear reducers.

Other Mini Motor Lines for High-Performance Plants

F Series – IP67 Protection and Food-Grade Compatibility

F Series motors are built with an epoxy-coated aluminum body, complemented by stainless steel screws, hubs, and food-grade lubricants. This configuration ensures IP67 protection, making them ideal for applications that require regular washdowns, such as conveying, dosing, portioning, and packaging systems. This design minimizes contamination risks and simplifies sanitation activities without compromising durability.

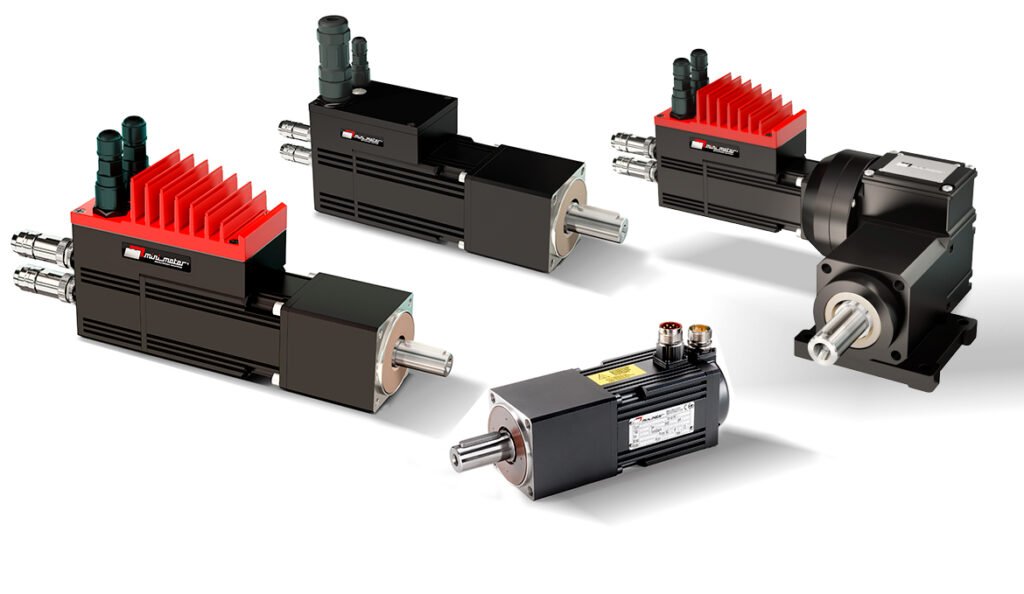

DBS – Brushless Servomotors with Integrated Drive

A flagship Mini Motor product line, the DBS series combines all the benefits of brushless technology with an integrated drive.

Their high performance, low energy consumption, and extensive customization options make DBS an ideal component for processes demanding both efficiency and versatility.

Available in four power ratings—125 W, 235 W, 345 W, and 660 W—the latest-generation Mini Motor brushless motors are low-voltage powered and feature 32-bit multi-turn absolute encoders.

Designed for continuous (S1) or intermittent (S3) duty, they come in versions with planetary gearboxes or worm gear formats. The DBS series also features a configurable digital output, and the optional STO (Safe Torque Off) function completes its specifications.

FC and FCL – Mini Motor’s Solution for Format Changeover

Our format-change range, operating at 24 V or 48 V, is divided into two categories: linear actuators (FCL) and rotary gearmotors (FC).

The FCL line, available in FCL100 and FCL200 models, is perfect for automating side guide movements in linear format changes up to 200 mm. These brushless servomotors can deliver up to 200 N and handle an axial load of up to 5 kg.

The FC line is available in FC3, FC6, FC10, and FC20 versions, depending on torque requirements. For the same torque, Fast Change offers twice the speed of competing alternatives, cutting format-change times by 50%.