Clevertech Group is a family run company with an inter national DNA, operating four production sites. The main production site is in Italy, where the HQ is located, covering a total of 36,000 square me ters, with an additional 10,000 square meters becoming operational in 2025. The other production sites are in Chang shu, China; Pune, India; and Ft. Meyers, Florida. Clevertech’s global presence includes several service hubs around the world, including in Thailand, Russia, Poland, Germany, France, the UK, and Mexico.

In 2024, Clevertech decided to expand its presence in the Gulf region by opening Clevertech Middle East and North Africa, based in Dubai. The continuous increase in automation demand in the GCC region and the significant presence of Clevertech equipment already installed in the area necessitated a strong local presence of a dynamic lifecycle service and sales team to actively support Clevertech partner.

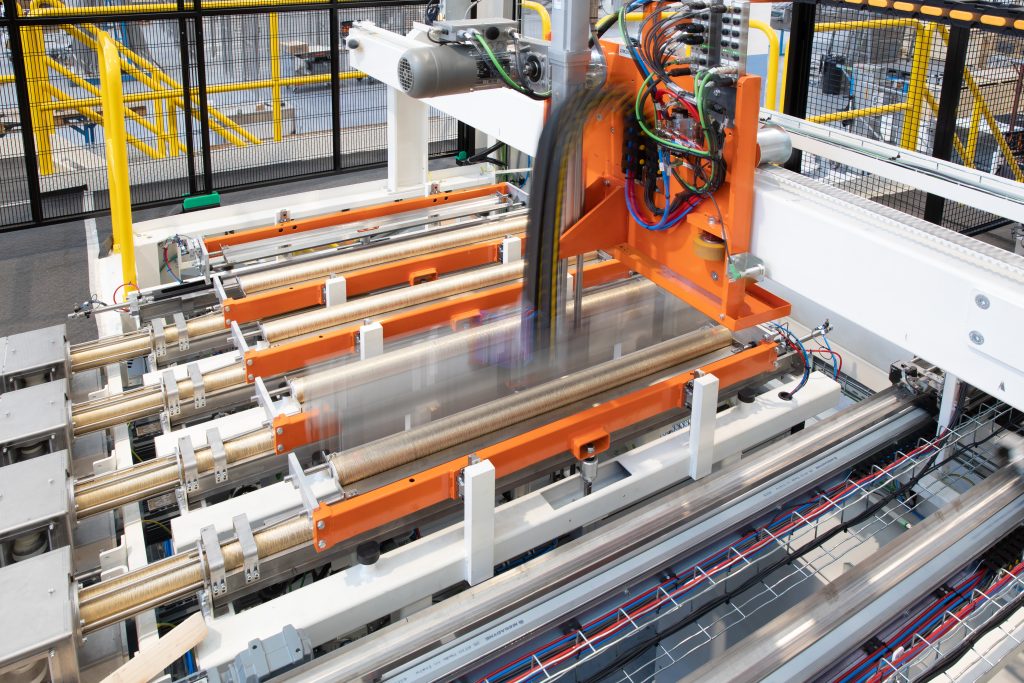

Clevertech’s portfolio of automation solutions includes depalletizers, loading and unloading systems for autoclaves with shuttle tray-basket handling, and end-of-line machinery such as case erectors, case packers, sealers, palletizers, and pallet stretch wrappers. These solutions are well-known among FMCG producers, especially at the multinational level, which represent 85% of Clevertech’s customer base. The engineering approach is characterized by customization, holistic design, and vertical startup, executed with state-of-the-art methods using the best TPM guidelines and programmed in open source with the PACK ML structure.

Clevertech’s unique project execution approach is a clear added value for the manufacturing and supply of complete systems within the food industry. The hardware and software adaptations to customer requirements, full customization of mechanical design per customer URS, and open-source programming that provides end-users with full access during machine operation offer complete control over the scope of supply.

This ensures clear cost control for equipment maintenance and monitoring OEE, with visibility of MTBF and MTTR values.

The software execution for product tracking and data management integration within the end-user ERP is another unique value offered in the food market. It brings significant savings by minimizing product changeover time and waste, maximizing the utilization of the production line, and ensuring seamless connection to the warehouse for finished product handling and upstream processing for product preparation.

The food market represents over 50% of Clevertech’s total turnover, equal to more than 150 million euros, successfully generated by over 400 fully motivated and talented employees working in the different Clevertech companies. Vertically connected to the food market is the market of cans and ends manufacturing, for which Clevertech is historically known as the best company in the world, producing the fastest systems available in the industry. In the GCC region, Clevertech’s cans and ends systems are widespread across all countries and have been actively supported with dynamic lifecycle services for decades.