OCTOFROST GROUP

OctoFrost, based in Sweden is a globally recognized supplier of food processing equipment with a deep focus on thermal treatment such as blanching, cooking, chilling, and IQF freezing. OctoFrost machines can be used for processing a wide range of IQF products and are designed with customers’ needs in mind: for a natural appearance of the products, reliable food safety, high yield and energy efficiency.

With global coverage of sales and customer service, the company has over 300 successful installations at customers located in more than 50 countries, across 5 continents. OctoFrost is committed to a world with better food quality and reduced food waste by improving solutions for freshly frozen food.

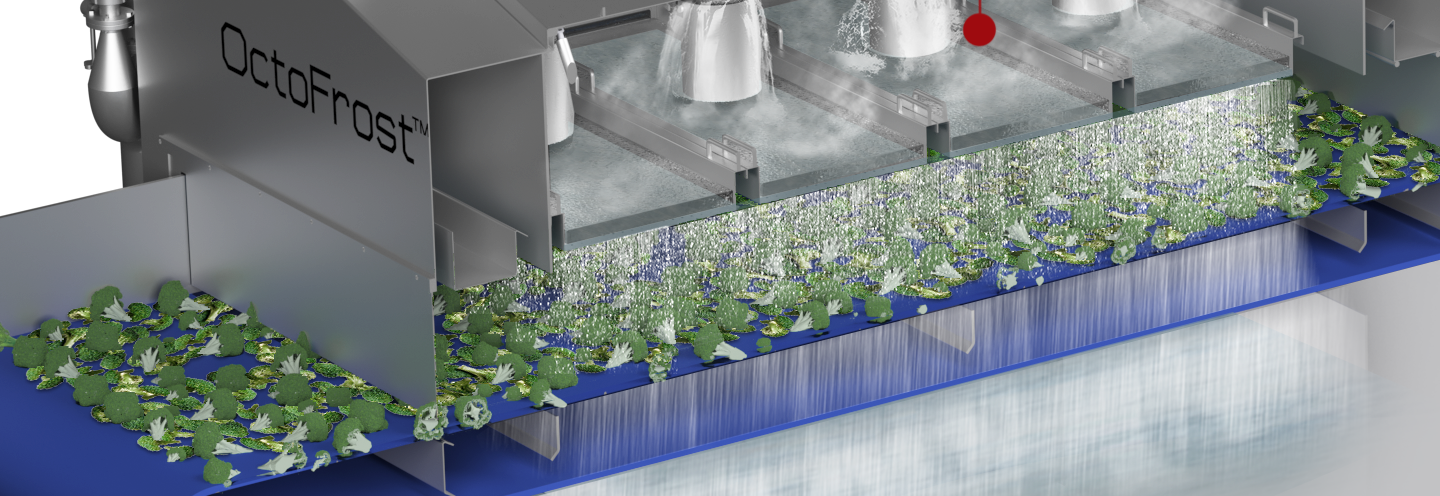

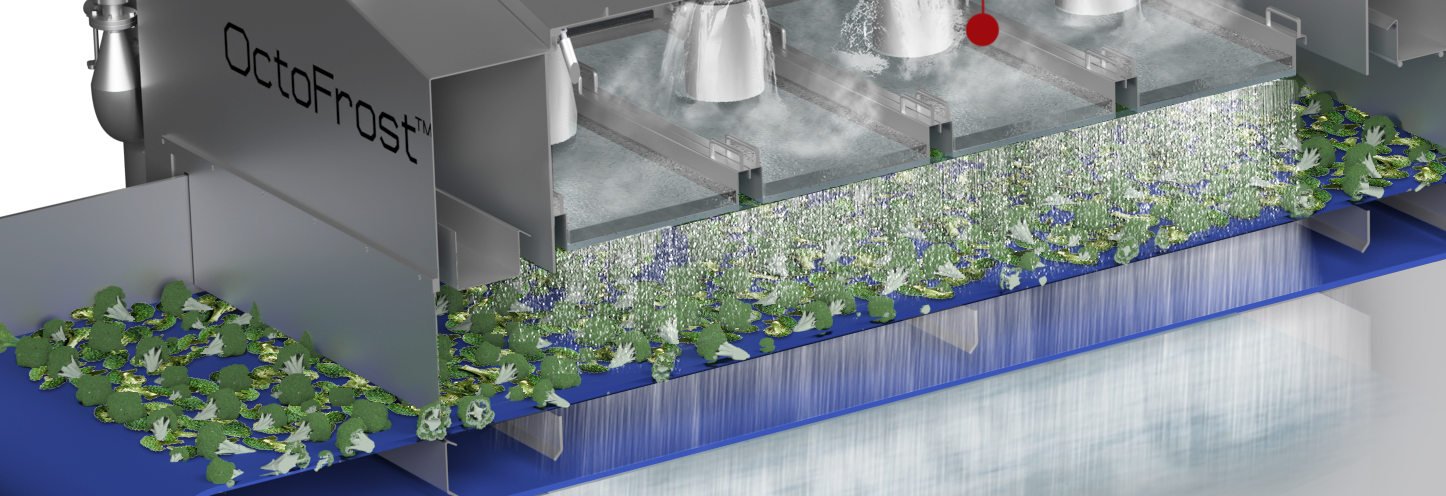

· The OctoFrost™ IF Blancher achieves the quickest heat transfer by means of a rain shower system. It allows accurate temperature control within 0.2°C to avoid over-blanching the product.

· The OctoFrost™ IF Cooker is the latest technological innovation in the shrimp processing industry. It uses the OctoFrost™ patented 3-temperature zones which avoids overcooking shrimp. This results in the highest yield possible.

· The OctoFrost™ IF Chiller offers a quick and efficient chilling process that improves yield and product quality. In the chiller, ice- water gently falls over the product through the rain shower system. The system is designed to reach a product core temperature of 5°C or less.

· The OctoFrost™ Tunnel Freezer is an innovative IQF freezer with a unique set of features. Designed for individual quick freezing of volumes between 500-15,000 kg/h, the OctoFrost™ IQF tunnel excels at handling sticky, fragile and otherwise difficult products.

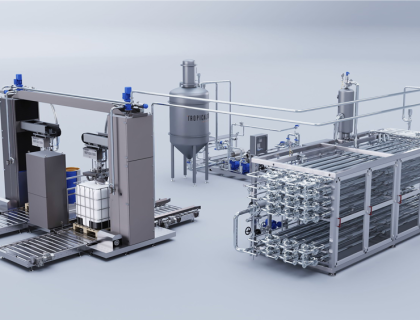

· The Impingement Freezer: With its compact design, the OctoFrost Impingement Freezer is suitable for static, flat products up to 25mm thick, such as hamburgers and chicken fillets, which are quickly frozen on a belt with high-speed air streams from both top and bottom