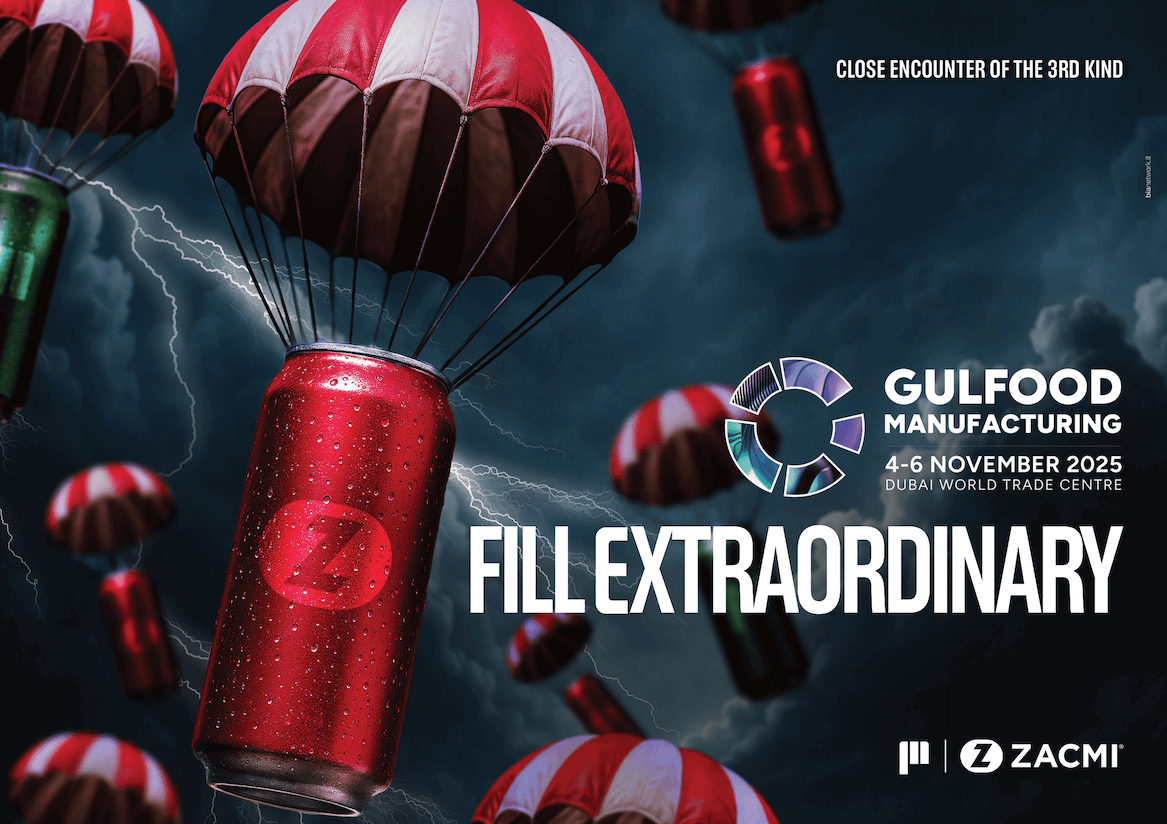

After an effective “alien” launch campaign and a “space-age” debut in Munich, ZACMI – a global leader in filling and seaming lines for the food & beverage industry – is bringing its latest technological masterpiece to Dubai: Be-Fill, an electronic, volumetric rotary filler designed to redefine standards in canned-beverage production.

While the machine won’t physically touch down at the show, Be-Fill will dominate the dialogue with ZACMI’s experts, offering visitors a fresh opportunity to discover how the company is launching itself into orbit in the beverage arena.

Maximum versatility

Be-Fill is capable of processing a wide variety of drinks:

• beer and carbonated beverages (between 2°C and 18°C)

• energy drinks

• juices and still products, in hot-fill up to 90 °C or cold-fill.

The machine handles aluminium and tin-plate cans with heights from 80 mm to 200 mm. Whether the product is sparkling or still, hot or cold, dedicated filling valves ensure optimal performance for each category.

“Extra-ordinary” performance

Available with 50 to 128 valves, BeFill can be integrated into a synchronised block with a seamer, also manufactured by the Parmese company. Format changeovers are lightningfast: the machine switches from can-end 200 to 206 with no manual adjustments, drastically cutting downtime.

All monoblock movements – from infeed conveyor through filler to seamer – are driven by brushless technology for perfectly synchronised, smooth operation.

Precise dosing, minimal waste

The electronic volumetric system measures the exact volume in every can, guaranteeing accuracy, repeatability and reduced product loss.

Hygiene and simplified maintenance

Product is fed from an external buffer tank via pump, keeping internal accumulation volumes low. Valves are fixed to the carousel with just two screws and have no external pneumatic connections, making removal quick and external surfaces easy to clean.

Three valve types safeguard performance and product integrity:

• dual-channel flushing valves to minimise oxygen pick-up in oxidationsensitive products while optimising CO2 consumption

• single-channel valves for standard products

• internal-recirculation valves for the pre-heating required in hot-fill applications.

A purpose-designed lower manifold optimises gas and liquid flows, reducing lubrication and maintenance needs. An innovative empty-can ejection system and easily removable hygienic covers further streamline upkeep.

Optional liquid-nitrogen dosing is available for producers seeking extended shelf-life and rigorous quality standards.

An invitation to look beyond

Drop by the ZACMI stand at Gulfood Manufacturing 2025. Even without the machine physically landing, Be-Fill will demonstrate how beverage production can soar to truly cosmic levels.