BBM Service is able to offer a 360° support and tailor-made service

Italian excellence.

BBM SERVICE is an Italian company with a long and renowned experience in the beverage sector, specialized in the turnkey supply of water and beverage bottling plants. Flexibility, speed, constant presence and ability to work on all the machines in the line: these are just some of BBM’s strengths. For more than 15 years, BBM has been a technical partner of some of the most renowned brands in the sector, such as Nestlé Waters, Coca Cola HBC, Refresco, Group, Heineken and many others.

A single partner, from audit to start-up

BBM Service is a single interlocutor with whom to interface for market and budget analysis, layout study, supply and installation of machines, management of safety protocols, and logistics. What are BBM Service’s turnkey services?

Excellence in used bottling machinery – delivered in 90/120 days

BBM has an impressive selection of 200+ used packaging machines, completely overhauled and updated, to ensure performance equal to the latest generation. BBM offers the best of the second-hand market, including blow moulders, fillers, labellers, shrink wrappers, wrap-around case packers, tray formers, palletizers and much more! Customers can see the machines and follow the overhaul and start-up process at the BBM showroom in Lenna (Bergamo, Italy) or at a distance.

Quality assurance

All machines are subjected to a complete series of tests. Any defective components are replaced with compatible spare parts to obtain maximum performance. For even greater security, BBM provides a 6-month full warranty on all its overhauled machines.

Available in just 90/120 days

After the customization phase of the machine, BBM’s specialized technicians are ready to carry out the transport, assembly, and start-up at the customer’s site.

Green investment

The growing problem of industrial material disposal makes it necessary to adopt a new philosophy, where old machinery is not demolished, but withdrawn from suppliers such as BBM. Buying overhauled means making a conscious, convenient, and environmentally friendly choice

Visit the BBM online store

At www.bbmpackaging.com you can browse the complete catalogue of used machines. Each page is complete with layouts, technical details, and videos of the machines in action. Contact info@bbmpackaging.com for a free quotation.

Technical assistance and engineering

With twenty years of experience and a team of over 50 qualified technicians, BBM offers a complete range of services to support the customer: disassembly and transfer of the line, format changeover, scheduled plant maintenance, and training. BBM also provides 24/7 remote assistance service.

What else? BBM offers its know-how for highly specialized engineering interventions. Their portfolio consists of machinery upgrades to fully exploit the potential of the machine and achieve energy and cost savings. BBM is specialized in upgrades on blow-moulding machines of all major manufacturers; Thanks to a few, simple installations it is possible to obtain a saving of 35% on energy consumption.

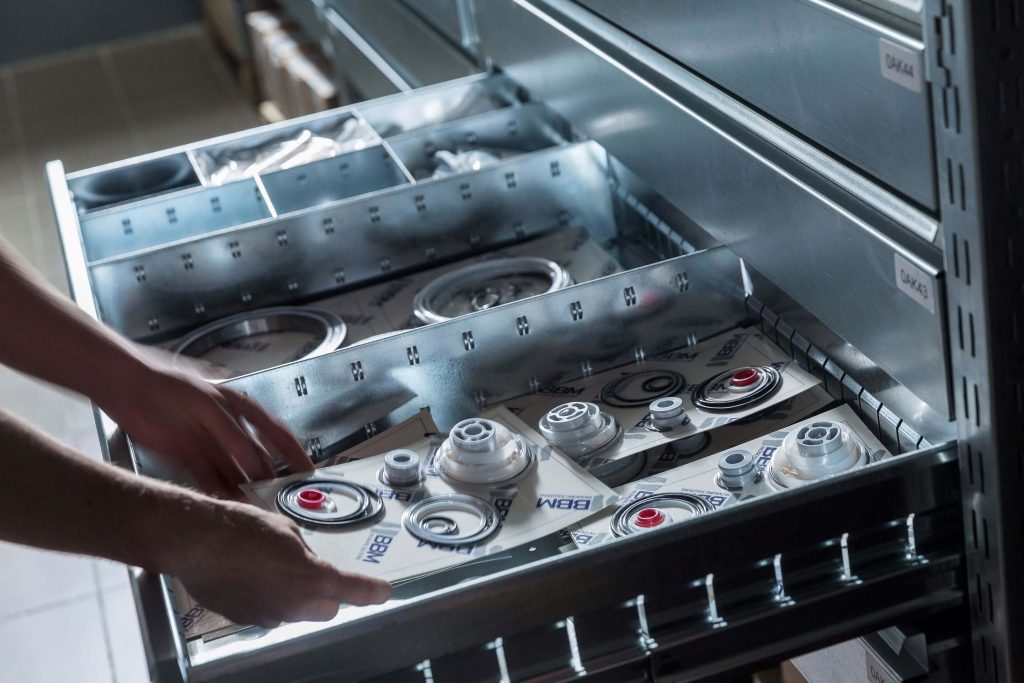

Compatible spare parts

Whether it is normal wear and tear or urgency, BBM is the best option for the supply of spare parts compatible with the machines of the main OEMs.

All spare parts are tested in a certified laboratory; in fact, BBM has always invested in research and development to provide customers with free pass material of the highest quality, at prices 10-20% lower than the market average. The vast entourage of foreign agents is responsible for facilitating commercial and logistics operations in the supply of spare parts in EU and EXTRA EU territories. Contact BBM Service for a free quotation info@bbmpackaging.com

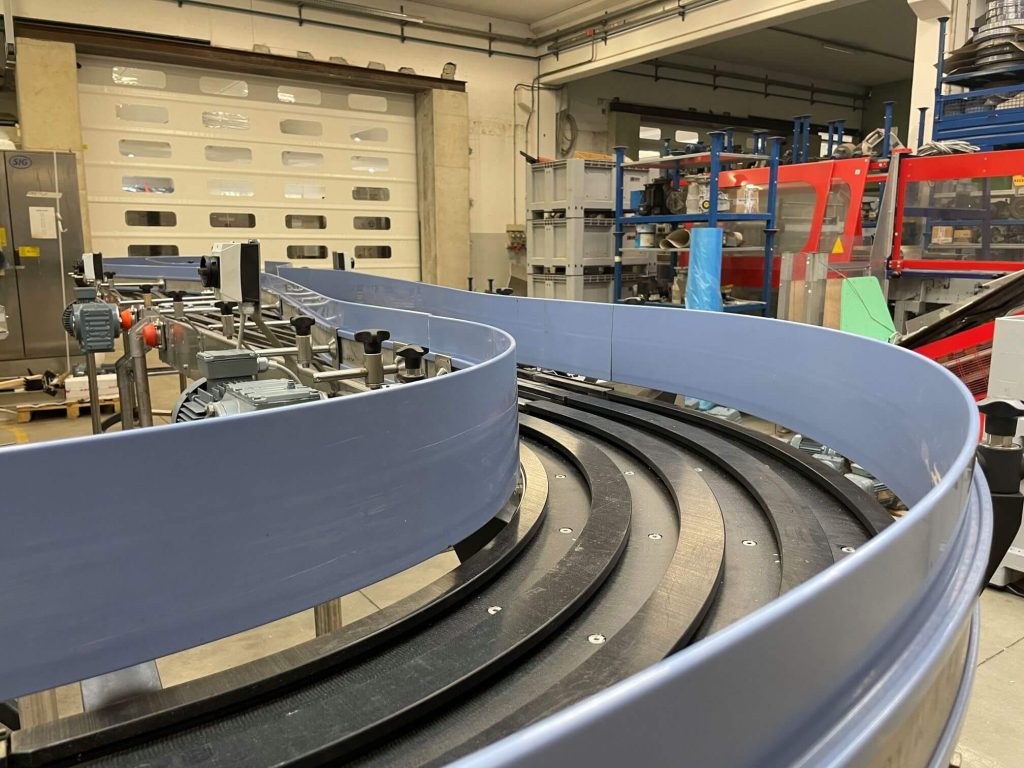

CAN YOU BELIEVE THESE CONVEYORS ARE USED?

Supply of revamped bottling line conveyors

Supply of revamped bottling line conveyors. Conveyor belts are one of the main components of the lines, they are the ones that manage the proper functioning of the whole plant and determine its speed. BBM specializes in supplying pack, bottle and air conveyors. What makes us special?

• Competitive delivery times; by reclaiming existing parts, BBM guarantee delivery of high quality material in short period of time

• The recovery of existing material. BBM Service’s engineering department is committed to recovering some of the old equipment, using the “cut and sew” technique. The goal? To optimize costs and promote sustainable investment. In fact, BBM’s mission is to give a second life to disused machinery. Reducing the disposal of heavy industrial material by recycling existing materials guarantees environmental and economic benefits that would not be achieved by buying new equipment only. BBM advocates a circular economy, which aims at not throwing away what still works.

But how? BBM restores elements in good condition and replaces worn components. An example of revamping includes the replacement of slide guides, drive and idler wheels, and the refurbishment of shafts. In the case of roller conveyors, it is also possible to repaint them, thanks to the collaboration with Colorsolution, a company that is part of the BBM group.

Not only that: BBM can carry out the adjustment of the containment guides and the automatic format change. The transmission via articulated joints and encoder boxes ensures maximum positioning accuracy, repeatability of adjustments and drastically reduced changeover times.

BBM exploits the original structure of the belts and recovers their motors, maintaining their mechanical seal and reliability. They carry out component revamping by integrating new and used/revamped components ad hoc, significantly reducing costs for the customer.

• Management software upgrade and re-layout

Thanks to the cooperation with exceptional partners, BBM can carry out upgrades on existing switchboards to improve the operation of production flows, also and especially in the function of new raw materials (e.g. reduced bottle weight). In addition, to improve the overall result, BBM Service’s technical department is dedicated to engineering the lines with possible re-layouts that optimize space and production. Thanks to their specialised technicians, BBM are able to offer tailor-made solutions, preventive maintenance, advice on the current situation and a flexible and fast field service.

In short, what are the advantages? Short delivery times, competitive prices and quality equal to the latest generation’s make us the ideal partner to support you in your future line revamps or ‘new’ supplies.