Unmatched Pizza Production Solutions

Rademaker provides trusted pizza production systems used by pizza makers worldwide, catering to every pizza style imaginable. Whether you’re aiming for artisanal quality with in-line pre-fermentation and proofing, or producing non-topped, fully topped, frozen, or fresh pizzas, Rademaker has the optimal solution. Their systems handle everything from thin crust to thick focaccia-style pizzas, offering production capacities from 500 kg to 6,500 kg of dough per hour, and up to 14,000 kg/hr for special cases. Working widths range from 600 mm to 1,600 mm.

Key Aspects of Rademaker Pizza Production Solutions:

- Excellent ROI due to a high performance and efficiency

- Great flexibility and a wide product variety

- Fast and easy change-over and cleaning

- Custom Solutions Available

Profitable Pizza Production:

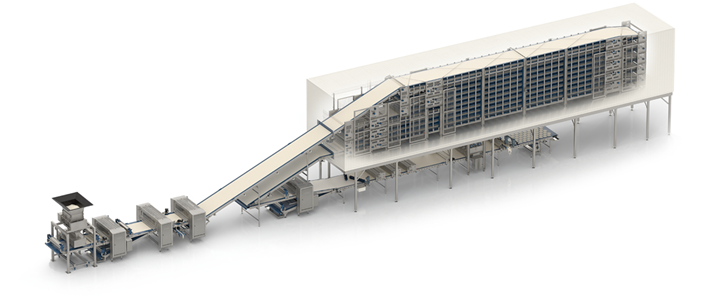

Pizza Base Production

The Rademaker Pizza Base line is tailored to your specific needs, producing sheeted or pressed pizzas in any shape or form. With working widths from 600 to 1,600 mm and capacities varying based on product and dough thickness. The design allows easy access for cleaning and minimal maintenance.

For high-class product quality, a proofer can be integrated for continuous dough sheet proofing or individual dough products.

Features:

- Handles a wide range of doughs, product sizes, and shapes.

- Efficient production with fast maintenance, cleaning, and changeovers.

- Meets the latest technical, hygienical, and technological standards.

Pizza Topping Line: Effortless Pizza Topping

Experience unparalleled ease and precision with Rademaker’s efficient and flexible Topping system.

This advanced technology applies a wide variety of toppings (including cheese, IQF products, and various types of meat) with exceptional accuracy, ensuring the best possible distribution.

- User-Friendly: Simple to operate and maintain.

- Hygienic Design: Meets the highest standards.

- Modular Flexibility: Quick product changeovers and minimal material waste.

Advanced Topping Technology

The upgraded applicator design ensures ultimate accuracy in topping application. Automatic recycling of topping materials eliminates waste, making the process seamless and efficient.

Complete Solutions for Pizza Production

Rademaker is your full-solution provider for both pizza bases and fully topped pizzas. The modular design offers great flexibility and a wide product variety, making your production more efficient. Rademaker systems are suitable for various pizza shapes and sizes, including pre-proofed and in-line proofing options, as well as alternative products like pizza baguettes and pizza sticks.

The Rademaker System Integration Team can also provide complete solutions for mixing, proofing, cooling, baking, and packaging equipment.

Trend Product: Pinsa

Pinsa consumption is growing. Compared to classic pizza dough, Pinsa dough has a different water content and lower yeast percentage. Rademaker has integrated the Pinsa production method into our lines, respecting the dough to provide a light texture and easily digestible Pinsa. With Rademaker solutions, industrially produced Pinsa matches the quality of artisan products.

Contact George Makdissy: Your Dedicated Rademaker Contact in the Middle East

Rademaker proudly presents George Makdissy as esteemed regional representative. With a dedicated focus on the Middle Eastern market, George brings a wealth of expertise to ensure you receive the best production solutions tailored to your unique requirements. With the newly established Rademaker sales office in Dubai, United Arab Emirates, George is committed to delivering top-notch production solutions tailored specifically for its valued Middle Eastern customers.

George Makdissy

+971 58 590 7915

+961 32 516 85

gmakdissy@rademaker.nl

Follow Rademaker on Social Media

LinkedIn | Facebook| Youtube