In primary packaging solutions, sustainability is expressed through creativity, with the design of visually appealing containers that capture consumers’ attention, and through functionality, with the development of lightweight, rPET, and label-free bottles.

In Portugal, Carvalhelhos, a company that has always prioritized sustainability and environmental responsibility, produces new PET and rPET containers with and without plastic labels, thanks to the EBS 8 KL ERGON stretch-blow moulder by SMI.

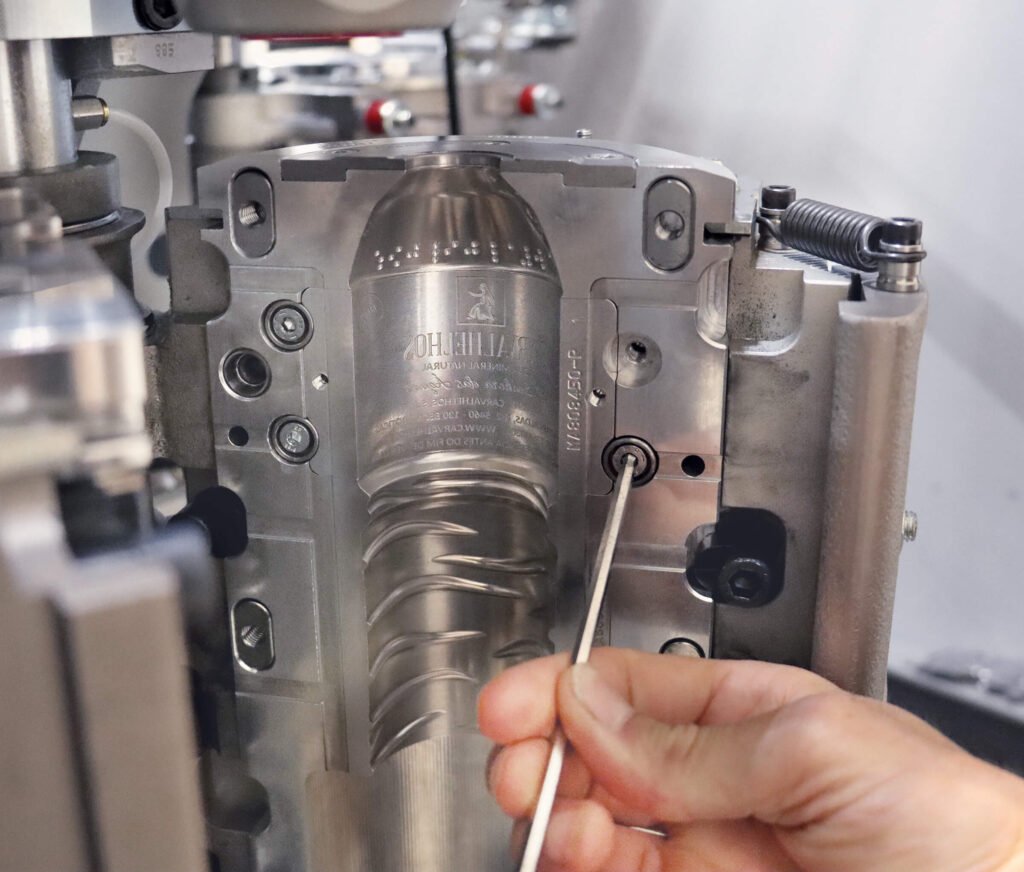

Carvalhelhos blow moulder not only produces traditional PET and rPET bottles that require label application, but it is also equipped with specialized moulds designed by SMIMEC for the stretch-blow moulding of 0.33 L, 0.5 L, and 1.5 L flat-bottom rPET bottles without paper or plastic labels. This eco-friendly solution eliminates the need for glue and additional paper or plastic materials, simplifying the recycling process and ensuring higher purity in recycled PET.

The area dedicated to the label has been removed, eliminating the ribs typically found in traditional bottles. Therefore, an innovative combination of embossed and debossed engravings on the bottle body provides additional space for the brand logo and essential product information, which would traditionally appear on a label. This approach also allows for the inclusion of information in braille.

Labels-free bottles. Advantages. For the environment and the consumer:

• eco-friendly solution, as the PET bottle is 100% recyclable

• better compliance with environmental regulations regarding recycling

• easier recycling process, since there is no label to remove. Even when made from recyclable materials, labels on traditional bottles must be separated from the container during recycling.

• no need for glue in label application.

• reduced packaging waste, resulting in less material to recycle.

For the bottler:

• reduced costs for raw material purchases (labels and glue).

• lower storage costs for raw materials.

• simplified and optimized production process, as a labelling machine is no longer required.

• easier and more efficient PET recycling, since there is no need to separate the label from the container.

SMI, through its subsidiary SMIMEC, takes care of the entire production phase of the moulds installed on stretch-blow moulding machines. To meet the needs of customers who wish to produce both traditional bottles intended for label application and bottles without labels, SMIMEC manufactures special couplings to be inserted in the moulds mounted on SMI stretch-blow moulders. Size changeover operations to switch from one type of bottle to another are extremely simple and fast as it is sufficient to replace the plug section in the mould.

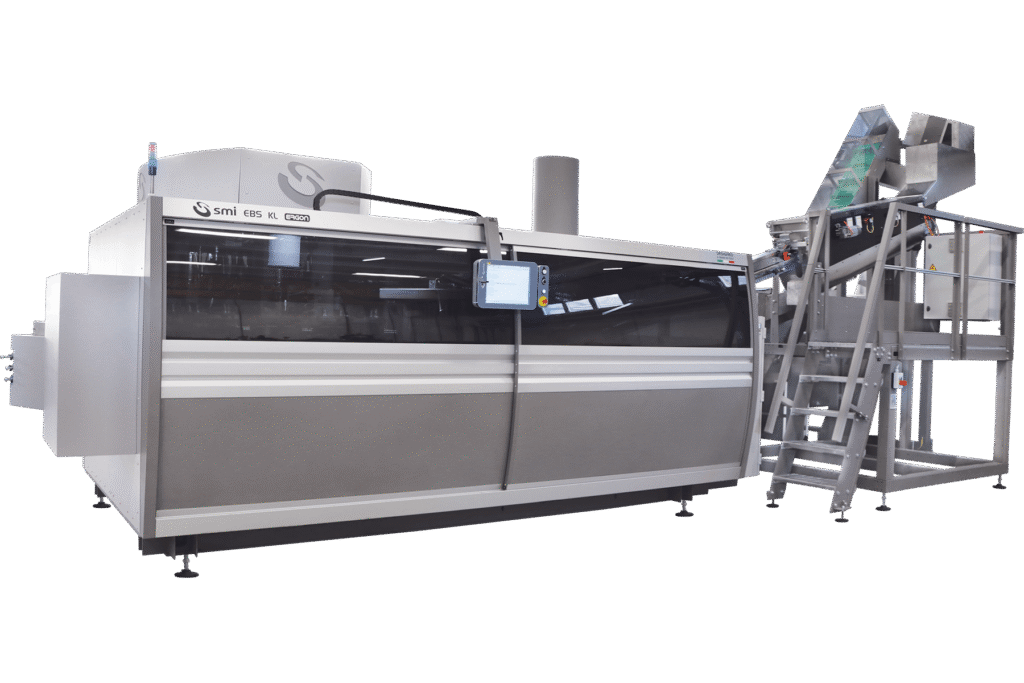

Focus on the EBS KL ERGON series

The rotary stretch-blow moulding system from the EBS KL ERGON series is a state-of-the-art, intelligent and interconnected system, equipped with the most modern automation and IoT technologies, with strong eco-compatibility characteristics and different benefits.

Management and control benefits

The system supplied by SMI uses an advanced automation system called MotorNet System®, which ensures the constant maintenance of the optimal processing parameters during the entire production cycle, allows the direct modification of the machine settings from the operator panel, simplifies format change operations and offers the possibility of temporarily disabling one or more moulds if necessary.

Energy – saving benefits

The stretch-blow moulder is quipped with a system of energy-efficient thermo-reflective panels in composite ceramic material, positioned both in front and behind the lamps, which allow uniform heat distribution.

The stretch-blow moulding carousel is equipped with motorised stretch rods controlled by electronic drives, which guarantee precision in operations and energy savings (no compressed air is needed and the power consumption is lower than solutions with linear motors).

Production efficiency benefits

The EBS KL ERGON stretch-blow moulder is equipped with high-performance valves and low dead volumes (-50%) which ensure reduced pre-blowing and blow moulding times and better quality of the bottles produced.

The blow moulding machine also adopts a series of measures capable of reducing the level of wear of the components to the benefit of production efficiency, such as the gripper handling system based on springless preform grippers/bottles equipped with desmodromic cams and plastic bearings.

Benefits for operator flexibility

Thanks to the preform feeding system equipped with adjustments by means of numerical position counters, format changeover operations are simple and fast. Even the format change operations, to switch from the production of traditional bottles to bottles without a label, are extremely simple and fast as it is sufficient to replace the graft section in the mould.