The Company, founded in 2005, has achieved a very good reputation in the beverage industry field, managing to cooperate with the major global players and with private investors installing new production facilities, quite often green fields, in emerging Countries.

WS continuously improves its standards to guarantee product quality, energy saving and maximum plant output while complying with the strictest criteria for hygiene and safety.

All the devices are entirely conceived and designed to guarantee the best requirements in terms of microbiological, physical-chemical and organoleptic properties; the entire production process and software development are managed internally, as well as installations and commissionings which are carried out with WS’ own resources.

WS’ products for beverage industry are:

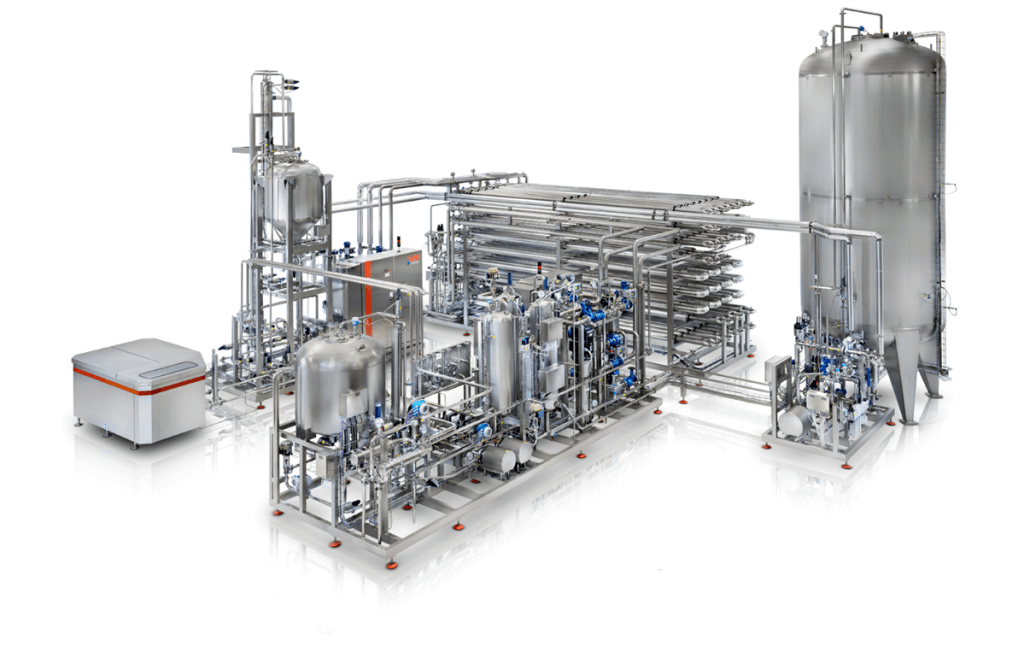

• water purification plants (mechanical filtration, microfiltration, reverse osmosis, UV disinfection, sterilisation) designed according to the Customer’s exigencies and the chemical analysis;

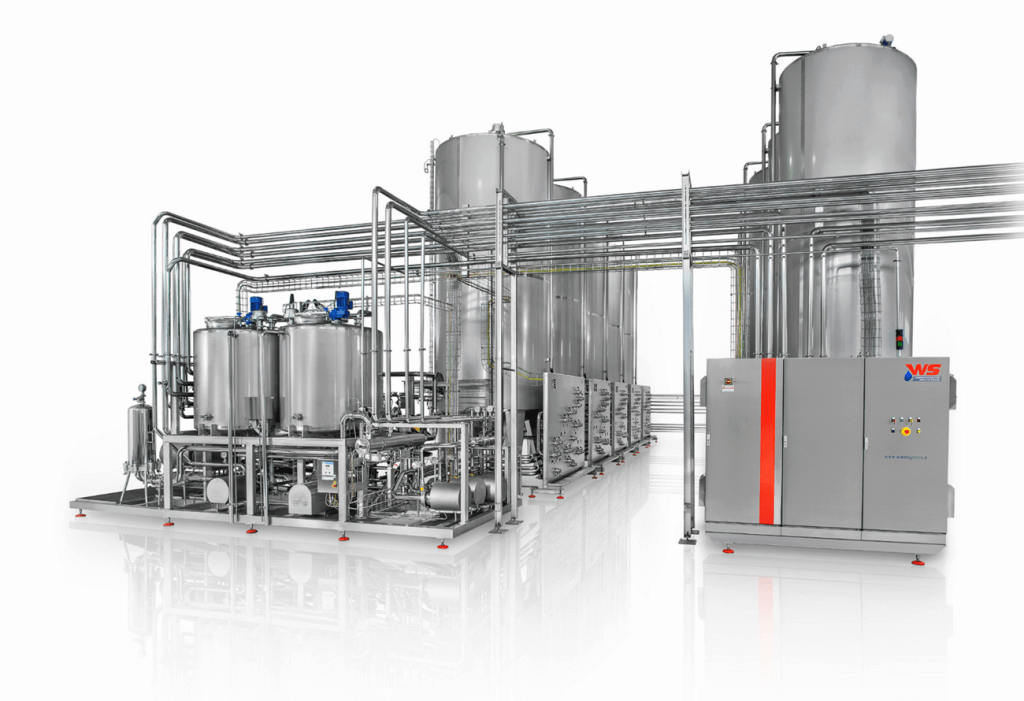

• sugar dissolving systems (single batch, double batch and continuous up to 35.000 l/h);

• semiautomatic and automatic syrup rooms;

• premix units;

• flash pasteurising units;

• ozone generators;

• carbonating equipments (water, wine, beer, soft drinks);

• in line syrup blending systems and ingredients mixing systems;

• steam sterilisable microfiltering systems (juices, beer, wine);

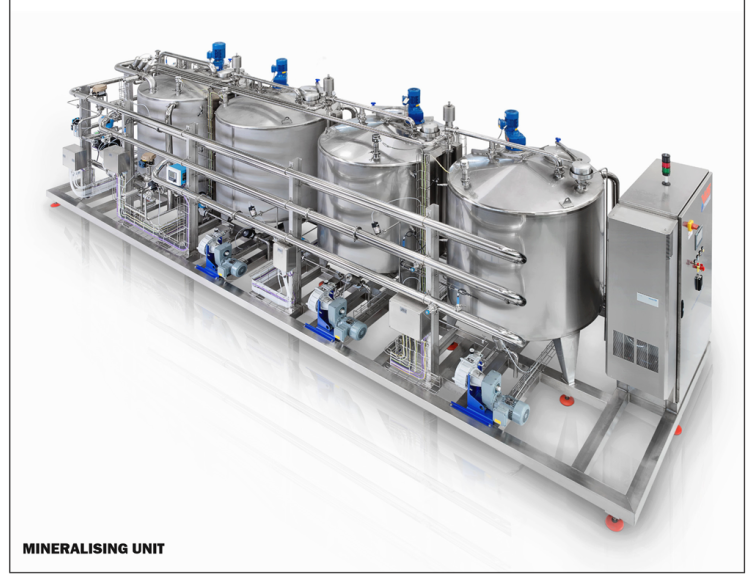

• mineralising equipments;

• equipment for preparation of non-chemical bottles rinsing and disinfecting solutions (such as ozone) and chemical solutions preparing devices (peracetic acid, hydrogen peroxide, chlorine, etc.);

• equipments for the preparation of sterile water;

• manual and automatic CIP systems.

WS offers a wide range of process equipment solutions for the beverage industry

Thanks to its skill and process expertise, today WS is widely present worldwide even with turnkey solutions including ancillary equipment (cooling equipment, boilers, etc.), pipework and wiring. WS’ philosophy is to manufacture high quality and reliable equipment, equipped only with top brand components:

ALFA LAVAL, ENDRESS+HAUSER, PALL, MASELLI MISURE, SIEMENS, FESTO, SPIRAX SARCO are the typical components our Customers will find on their plants. The choice of providing only state-of-the-art solutions has brought us to be appointed by ALFA LAVAL as officially “Authorized Integrator” some years ago and as “Master Integrator” recently. All the aspects are carefully arranged. Each process is designed according to the real Customer’s needs. During the years, WS has been able to develop innovative solutions, sometimes unique in the field.

WS consider Customer Service one of the greatest keys to success: entire business, marketing, sales and profits depend on Customers’ satisfaction so the after sales team is constantly trained to perform the simplest solution in the shortest possible time to support the Customer’s business.